TALK: Offsite Construction

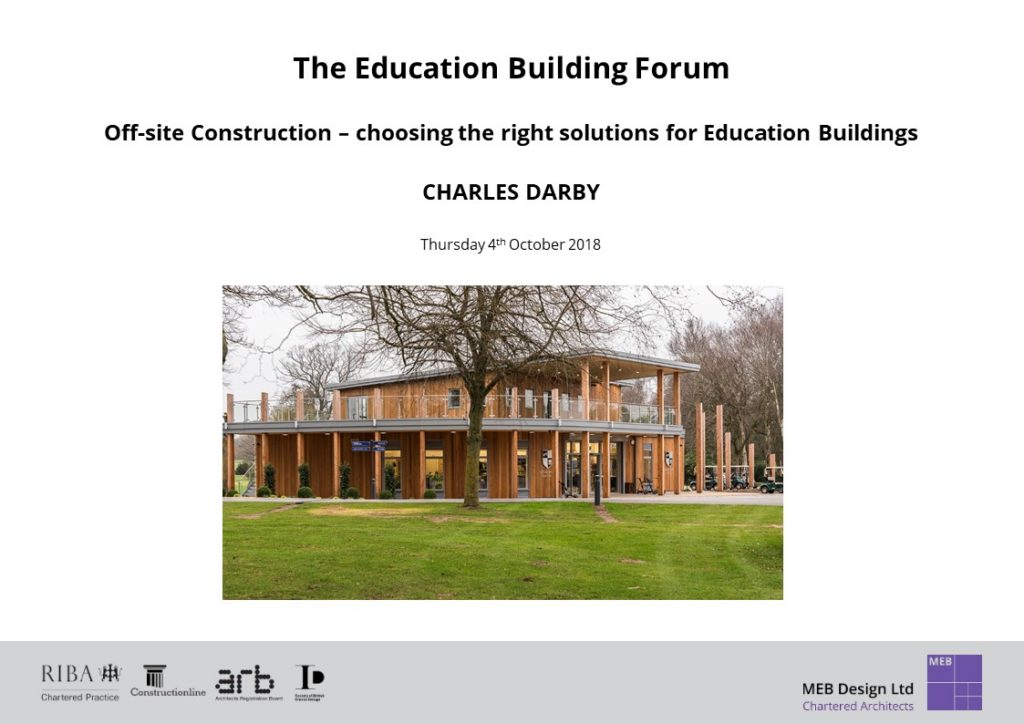

On Thursday 4th October MEB Design Director Charles Darby gave a talk at the Education Building Forum at Whittlebury Hall in Northamptonshire. The talk was part of a series on the subject of Offsite Construction and was entitled “Offsite Construction – choosing the right solutions for Education Buildings”. Check out the abridged version of his talk below.

Charles Darby has been a Partner, then Director, of MEB Design since the late 1990s (for over 20 years) and is the lead Director for MEB Design’s “Learning Communities” or Education Sector. He has been working with and designing school buildings for his whole career.

MEB Design was first established in 1983 and has specialised in Education buildings ever since. 35 years on over 30% of MEB Design’s work is in this field and it is their largest sector. In considering this subject it is important to be clear about the terminology. During this seminar some people have already referred to “Modern Methods of Construction” or “System Building” or even “Prefabrication”. Other terms which are used include “Modular” or “Volumetric” building. The industry seems to be settling on the term “Offsite Construction” to be the umbrella for all of these. This talk will explore some of these methods, and some others, by using examples to consider which methods are most suitable for different scenarios.

Most people will recognise this as a typical temporary classroom building. This was a classroom village by Excel Modular, established while the Junior School at Hoe Bridge was rebuilt over the course of an academic year. It was very successful and very appropriate, and some teachers liked these classrooms better than their permanent ones! They did not, of course, have to look at them from the outside.

Temporary or modular buildings do not have to look like this. These innovative buildings by Green Unit are based on timber hoop modules and can be built to any size (like an extruded tube). They have high sustainability credentials and are designed to Passive House principles. They can be more or less permanent, with removable foundations.

Moving on to more permanent buildings, this Early Years’ Building, constructed by Modulek for Danes Hill, is a simple, single-storey building, with outside space and a canopy, and is very successful in its context between other buildings. These buildings are based on standard “volumetric modules”, delivered on the back of a lorry, but are obviously restricted in their design, layout and flexibility.

Another type of Offsite Construction is timber frame or “panelised construction”, and this 50-bed Boarding House at Uppingham School probably doesn’t look like a typical timber frame building. This is, in fact, a series of 2 – 3 storey timber frame blocks, connected by glazed links. The main reason for the timber frame design on this project was to reduce the time on site, which ended up having to be only 8 months, due to Planning delays and bats!

Timber frame construction looks like this – prefabricated wall and floor panels, stacked on top of each other as the superstructure, and then clad and finished in different materials. This building at Uppingham also had En-suite Bathroom pods, which will be discussed further later.

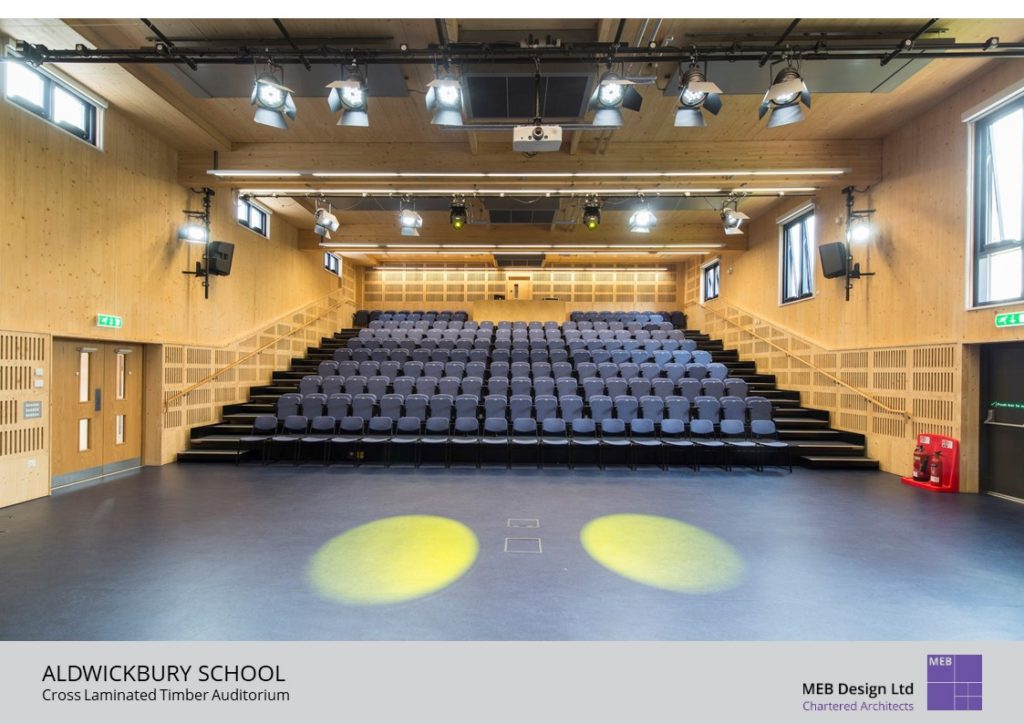

Another type of timber panel is Cross Laminated Timber or CLT, which was used here at Aldwickbury School. MEB Design has used this material on a number of projects and it can be expressed as the finished surface if detailed and protected appropriately. It also has good environmental performance including thermal, acoustic and air-tight qualities.

The panels are pre-machined and brought to site like a kit of parts, to be quickly and simply craned off the back of a lorry and assembled. A good degree of up-front design and co-ordination is required to ensure accuracy.

The main benefit of CLT construction is that it is quick and clean and creates a safe working environment more quickly. This project (not actually a school) had the superstructure erected, with floors, stairs and roof, all in just over 2 weeks.

The project is a Golf Club building and was nominated for a number of Offsite Construction and Structural Timber Awards.

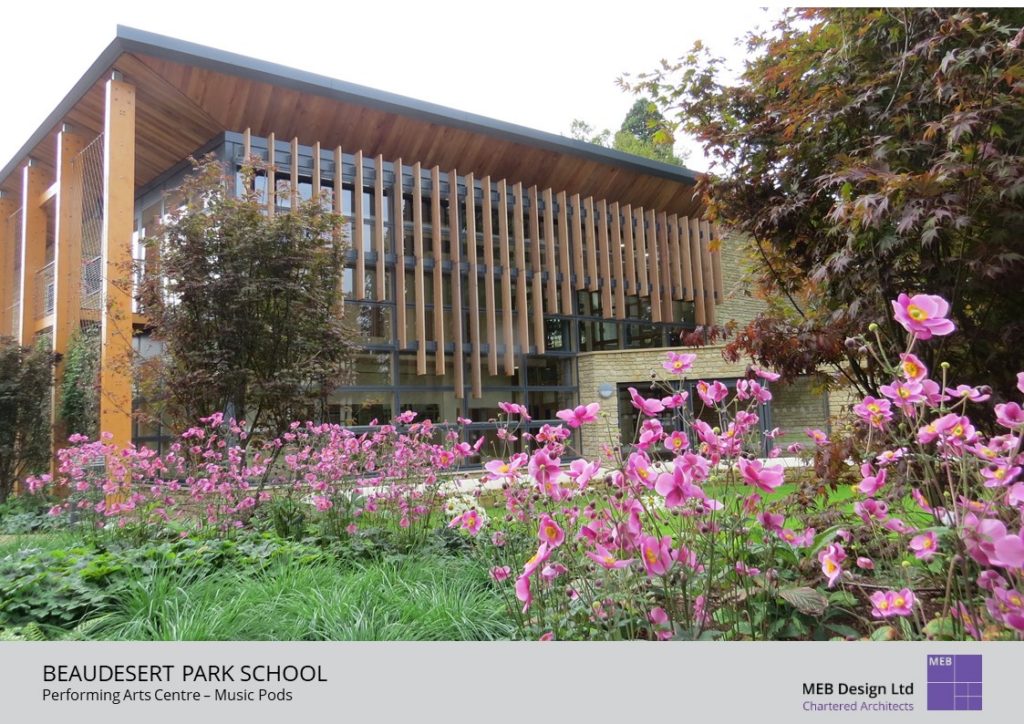

Not all buildings need to be entirely made with Offsite methods, but they can still benefit from the principles. This Performing Arts Centre at Beaudesert Park was nominated for an RIBA Regional Award. It is a traditional steel frame construction, but it contains Music Pods in the basement.

This meant that the basement area could be finished first, as a simple shell, and the Music Pods, by Amadeus Boxy, were brought in and assembled on site over a matter of days. These included practice rooms of different sizes and even a drum room. As a result, the Music School part of the project could be handed over well in advance of the rest of the project.

As mentioned previously, another modular or “offsite component” that many people are familiar with is the Bathroom Pod. MEB Design has used these in many locations, and this project for Wycliffe Hall, part of the University of Oxford, involved the refurbishment of 2 large North Oxford Victorian houses to provide En-suite Student Accommodation.

Completed over the Summer holidays, the Taplanes pods were carried in in sections and quickly installed, partly pre-plumbed and fitted out internally. The finished product is crisp and clean and high quality, and the pods were simply plaster-boarded around to fit neatly in the corners of the rooms.

Hopefully these illustrations show that there are many different aspects to “Offsite Construction” and that clearly there is a not a “one solution fits all”. However, there is definitely a time and a place for these methods and architects should be able to advise and assist in making the right choices at the right times.